Here in manufacturing at ColonialWebb, we are referred to by many different names within the company. For example, you might hear someone call us “the shop,” “fab shop,” “prefabrication shop,” or “the controlled environment.” Most of these are acceptable names when referring to us on the fly, however, some can carry half definitions of what we do. At the core of it, there are two functions that the shop performs: Prefabrication and Manufacturing Products. Let me explain the difference between the two.

Prefabrication is the partial making of something before the finalization of the actual product.

Think about a racked system on wheels that contains multiple runs of piping racks that are numbered from 1 to 10. This rack contains a line in the drawing that must be eventually connected with other components onsite. That is prefabrication and it serves as a time saver for installations.

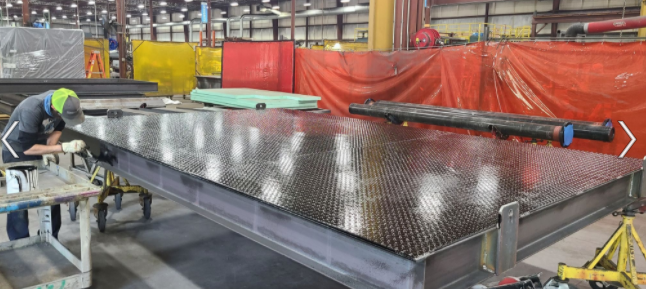

Manufactured Products are built as complete units or systems. For example, mechanical skids are complete by design and need to be placed in position to be hooked up.

Let’s take sheetmetal duct (a manufactured product) for instance — did you know that none of the sheetmetal duct you see on a jobsite is made on a jobsite? That’s right… Typically, all of it started as raw material in our shop that comes to us in large rolls of metal called coils (first photo below). After some cutting, forming, fitting up, and sometimes welding, complete products are made (bottom two photos)

Although we may be called many different names, there is one thing that we have in common here in manufacturing — we are a team that works together daily to support our construction, special projects, and service teams across our seven locations. If you have an idea or drawing on paper, we bring it to life.

If you have interest in any of our manufacturing services or capabilities, be sure to check out our page at colonialwebb.com/manufacturing.